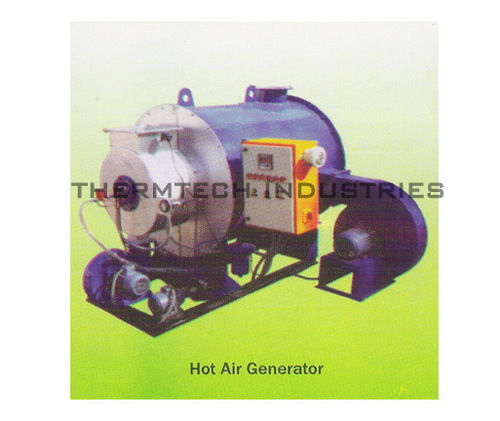

Direct And Indirect Hot Air Generator

Product Details:

Product Description

The ( FBC ) Fluidised Bed Combustion fired HAG system consists of a fluidized bed furnace, settling chamber and high efficiency cyclones. Hot air with minor dust particals having size lower than 20 microns from our hot air generator, enters the process.The total system is automated.

FBC Furnace with wind box :

Agro waste / Coal / Lignite fired FBC system comprising of a Nozzle plate with attached Air Plenum, a side structure frame bolted with Nozzle plate. Graded cast iron Nozzles fitted on top of the Nozzle plate and Sand drain pockets are provided for the removal of heavy unwanted silica particles.

Fuel feeding with screw conveyor system

M.S. Fabricated Fuel feeding venturi system is provided for feeding the fuel inside the furnace through S.F.D. Fan air.

Refractory material:

All the standard / special shaped refractory bricks for furnace walls along with fixtures and holders are provided. The required Insulation bricks Mortar cements will be provided by us( for Furnace area Refractory work only).

Instrumentation and safety interlocks:

The system offered is extremely simple and convenient to operate. Alarms and safety interlocks have been provided to ensure correct working of the HAG. The following are a few of the safety inter locks.

- Unless process suction fan is switched on, F.D.Fan / S.F.D.Fan / Fuel Feeders will not operate.

- In case of high hot air temperature, audio/visual alarms are activated on the panel.

- In case of high bed temperature audio/visual alarms are activated on the panel and fuel feeder speed is lowered down to minimum.

Control panel:

The panel is PLC based, having sophisticated but user friendly controls enabling the operator to run the HAG in automatic or manual mode as desired. The control panel consists of main MCCB, invertors for fans and feeders with individual MCBs, annunciation module with hooter, PID controllers, indicating lamps and one auxiliary contact.

Technical Specification

| Capacity : | 4 Lac Kcal/Hr to 40 Lac Kcal/Hr |

| Firing mode : | MANUAL & AUTOMETIC SYSTEM |

| Fuel : | Coal/ Wood/ Husk/ Lignite/ Sawdust Etc |

| Pass | 3-4-5 Pass |

| Furnace : | Manual & FBC |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+